Custom Open Die Forging Manufacturing Capabilities

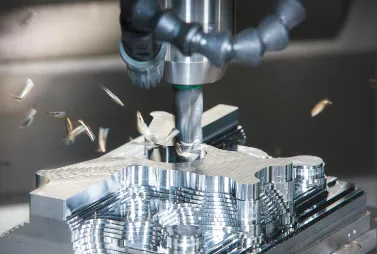

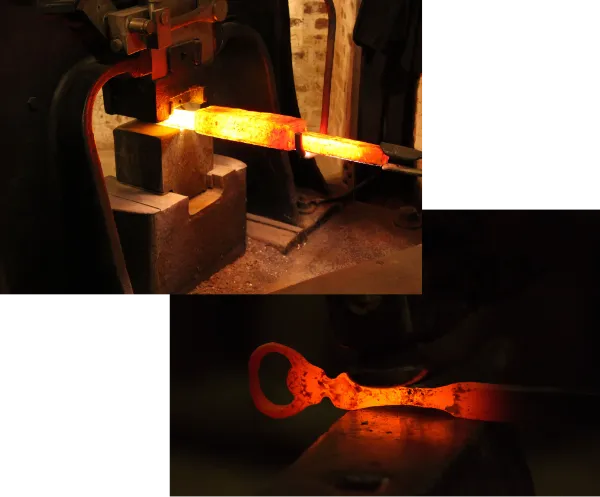

The open die forging process consists of contorting a piece of metal between 2 separate dies. The metal is then manipulated through die pressing the material through a series of movements until the desired shape is achieved.

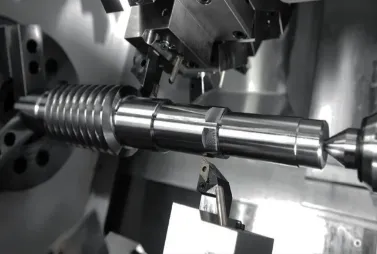

The metal products created through the custom open die forging process usually need secondary machining and refining to achieve the tolerances required for the finished specifications. Open die forgings are often used for parts that are basic, rather than advanced, in design, such as discs, rounds, sleeves, cylinders and shafts.