CNC Machining Services

Forgings offer superior strength, good dimensional accuracy, and many other benefits, but their complexity and tolerances are limited. That's where CNC machining services come in. Standard and large-format CNC machining services produce exceptionally accurate specifications, refining forged parts to achieve tight tolerances that would be impossible to accomplish through the forging process alone.

Your One-Stop Source for CNC Machining of Forgings

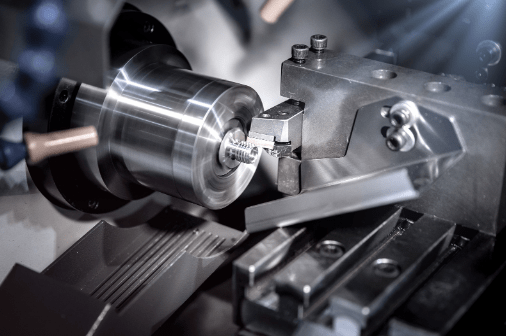

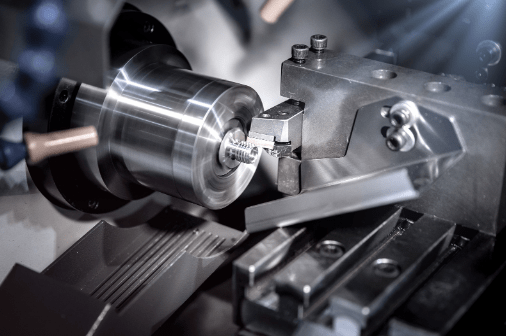

At Great Lakes Forge, in addition to producing custom forgings through our industry-leading open-die forging process, we offer highly technical CNC machining services for forgings that require tight tolerances and complex dimensions. Our expert machinists use our large-format CNC machining capabilities to produce finished parts that achieve even the most strict tolerance requirements. Our CNC Machining processes control complex machinery like grinders, lathes, mills, and routers to carry out turning, milling, boring, and facing operations. At Great Lakes Forge, you can get all your custom forging requirements and complex machining capabilities in one location.

Benefits of Choosing GL Forge for Your CNC Machining Needs

- Reduced Lead Times: We streamline your project as your single source for both forging and machining.

- Enhanced Quality Control: We maintain consistent quality throughout the entire manufacturing process.

- Lower Costs: We eliminate the need for multiple vendors, reducing overall project expenses.

- Convenient One-Stop Forging & Machining Solution: You can get fully finished parts with tight tolerances all from one convenient location.

What CNC Machining Processes are Available at GL Forge?

CNC Milling

Our CNC mills run on programs comprising number- and letter-based prompts that guide pieces across various distances. The programming employed for a CNC mill machine could be based on either G-code or a unique language developed by a manufacturing team. Basic mills consist of a three-axis system (X, Y, and Z).

CNC Turning

GLF's CNC-controlled turning lathe functions by securing and rotating the product being machined along a dual axis of movement at high speeds. A single-point cutting or boring tool shapes the material, creating the desired component. The CNC turning lathe is controlled by computer programs, ensuring that the exact same components can be produced and reproduced with systematic precision.

Large Format CNC Machining for Superior Accuracy Repeatability

Great Lakes Forge's large format CNC system can accommodate round or cylindrical parts up to 18" in diameter. We can turn parts up to 76" long to match the tight tolerances of our customers' designs. We can bore or drill holes up to 18" deep in parts up to 53" in length.

Our CNC machining software retains customer design files and specifications for future orders. If you need to reorder a custom forged and machined part or component one, two, or ten years from now, it will be identical to the original part Great Lakes Forge provided.

Material Options for Our Machining Services

One of our greatest strengths at Great Lakes Forge is our investment in a wide variety of inventory in grades of stainless steel, carbon, and alloy steel that allows us to meet your custom forging deadlines. We have built and maintained good relationships with material steel suppliers to ensure competitive pricing, excellent quality, and timely deliveries. We provide the following CNC Machining Service material options:

Industries That Utilize Our CNC Machined Forgings

We provide CNC-machined forgings for customers in a wide range of industrial sectors. From rugged crankshafts and spindles to custom components with complex specifications, we produce essential metal components for some of the most demanding applications. Industries we serve with our CNC machining services include:

Contact Us to Get All Your Forging & CNC Machining Services in One Location

Contact us for more information regarding our CNC machined forgings, or request a quote for further pricing details today. Great Lakes Forge is your trusted source for all your open-die forging and CNC-machining services.