Custom Open-Die Forged Parts

At Great Lakes Forge, we produce custom-forged metal parts through our open die forging process, transforming raw metal into custom shapes. Custom forging provides a cost-effective way to produce parts with distinct sizes and shapes that can be used for all types of applications. If your project requires a part or component that is tough, rugged, and crafted to your unique dimensions, custom open-die forging at Great Lakes Forge is your solution.

Benefits of Custom Parts Created by Open Die Forging

Custom forged parts offer a range of benefits for industrial applications. Some of the primary benefits include:

- Custom dimensions and shapes tailored for each application's requirements

- Flexibility on the size of the custom part, with the capacity to make very large components

- The open-die forging process improves grain structure and properties of the workpiece

- Wide range of material options

Shape Options for Custom Forged Parts

Whether you need custom-forged parts in unique dimensions or standard shapes, Great Lakes Forge has you covered. Our custom-forged shapes, blocks, flats, rounds, hubs, and more are made to your specifications. Manufactured from only the finest materials, our open-die forged parts can be modified to meet your application requirements. From blocks and flats to spindles and stepshafts, Great Lakes Forge can produce all your custom-forged parts needs.

Blocks & Rectangles

Forged steel blocks are considered a raw supply product, even though they are extensively worked and refined to improve the properties of the metal. Forged blocks and rectangles provide greater strength over standard plate or bar steel are valued for the enhancements they lend parts for performance in high-pressure environments, applications in which corrosion resistance is important.

Flats

Forged flats provide superior mechanical qualities over standard plate or rolled bar products. The flats can also be easily forged with a minimum thickness of 2.5" and in sizes up to 24" wide and 144" long. Our customers count on us to produce the high-quality forged flats they need with some of the industry's fastest turnaround times.

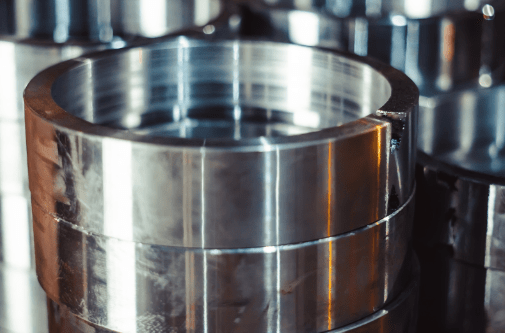

Rounds, Discs & Sleeves

Individually forged rounds and discs with a 3 to 1 minimum reduction can greatly improve the properties of your part, thereby reducing the risk of any voids or imperfections. These shapes are produced utilizing our open-die forging process combined with our state-of-the-art custom computer software, which increases accuracy, ease of replication, and speed of production time, thus saving you money on your part.

Hubs, Spindles & Stepshafts

With our advanced in-house machine shop we can create fully customized forged hubs, spindles, and stepshafts to your exact specifications in a variety of materials. Hubs, spindles, and stepshafts provide greater strength and fatigue resistance with continuous grain flow.

Custom Forged Crankshafts

Forged crankshafts provide strength and reliability that far surpass any cast or turned bar stock, making forged crankshafts the standard for any use that demands strength, consistency, or quality. In our heat treatment facility, we can stress relieve, normalize, harden, or temper your custom crankshaft to your specific requirements.

Steel Shafts

As a premier forged shaft manufacturer, Great Lakes Forge can produce forged steel shafts weighing up to 4,000 lbs. Our stainless steel lead times are the best in the industry, often 2 times faster than our larger competitors. The quality of steel shafts that we create are of far higher quality than shafts machined from bar stock. This is due to the quality of our forged steel shafts.

Stainless Steel Blocks

We offer quench-and-temper heat treating, milling & machining, ultrasonic testing, and mechanical testing to create the best finished stainless steel blocks on the market. We can manufacture high-pressure forged stainless steel blocks that provide excellent corrosion resistance and a finish perfect for several applications.

Stainless Steel Fluid Ends

A forged fluid end provides increased strength and reliability over otherwise identical fluid ends produced from bar stock or by other means. Our forged fluid ends set the standard for strength, consistency, and quality. Fluid ends provide improved microstructure, continuous grain flow, and higher fatigue resistance.

Materials for Custom Forged Parts

Great Lakes Forge carries an extensive selection of materials to suit all project needs. Our inventory includes advanced quality materials like 13-8 Stainless Steel, providing superior performance in the most demanding industrial applications. We also stock a range of other stainless steel, alloy steel, and carbon steel grades that provide the results you demand, no matter the circumstances.

With over 100 types of materials in stock, we can produce custom-forged parts in the material you need quickly and easily. If you don't see the quality forging material you are looking for, contact us. We have access to a wide range of providers.

Industrial Applications for Custom Open Die Forging Parts

Numerous industries worldwide use forged parts and shapes. Custom forgings provide the backbone, skeletal structure, and inner workings of an abundance of heavy-duty machines that drive the world's industries. At Great Lakes Forge, we open-die forge custom parts for rugged industrial applications. Some of the industrial sectors we produce custom parts for include:

Your Source for Custom Open Die Forging Parts & Services

At Great Lakes Forge we offer numerous premium quality custom services for your advanced project needs. Our services include CNC Machining, CNC Milling, CNC Turning, Saw Cutting, Deliveries, and more. Great Lakes Forge provides a complete line of forging services to handle all your project requirements, no matter what.

Contact Us to Learn How We Can Be Your Open Die Forged Parts Supplier

For more information regarding our custom forging products, get in touch with our sales team or request a quote for direct pricing information today. Great Lakes Forge is your trusted source for premium quality custom-forged parts and shapes.