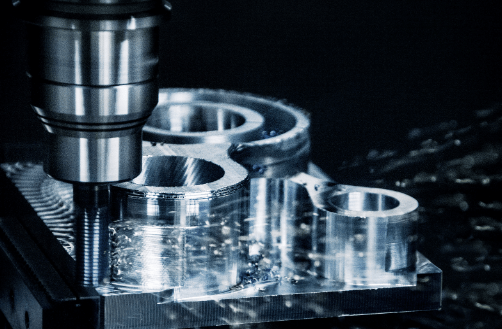

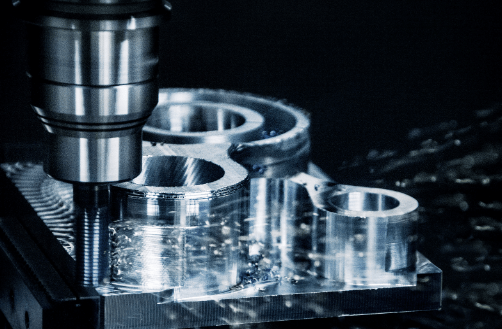

CNC Milling Services

CNC milling is a type of machining service similar to drilling and cutting. A cylindrical cutting tool rotates in numerous directions for increased precision. While a standard drill can only achieve single-axis motion, CNC milling workpieces can be moved across the milling tool in specific directions, expanding overall production capabilities.

Your Full-Service Destination for CNC Milling & Forgings

At Great Lakes Forge, our CNC milling services supplement our renowned open-die forging services, broadening our manufacturing abilities and providing you with exactly what you need. We can create numerous shapes, slots, holes, and other specialty impressions for a variety of projects.

As a smaller, privately owned metal open-die forging manufacturer, Great Lakes Forge’s metal forging services provide shorter lead times than our corporate competitors. We work directly with you to provide exceptional service for your CNC milling parts needs.

Contact us for more information regarding our CNC milling services for your custom project needs, or call us at 800-748-0271, and we will gladly answer any questions you may have. Great Lakes Forge is your trusted resource and partner for advanced CNC milling services.

Start Your QuoteCustom CNC Milling Capabilities from Great Lakes Forge

GL Forge uses custom CNC milling efforts to enhance forged components, with services including:

- Part Prototypes

- Complex Short-Run Production Parts

- Precision Components

CNC mills produce very little waste, reducing costs and preserving the amount of material required for projects. This allows us to use our CNC milling equipment to create prototypes at lower costs, helping refine forged parts for individual orders. Completed prototypes can then be manufactured in short production runs, producing complex parts efficiently and rapidly.

Our expert forging processes excel at forming custom requests, and our CNC milling capabilities enhance forged parts to produce precision components. The extreme efficiency of CNC milling processes reduces the time required for custom projects while improving the precision and quality of manufactured parts.

What Materials Are Available for CNC Milling?

At Great Lakes Forge, we pride ourselves on our comprehensive inventory of steel materials to meet all your custom forging demands. Specific CNC machine tools must be used for distinct materials, and GL Forge has the capabilities to successfully perform precision CNC milling on our steel alloys. Additionally, we consider the density of your chosen material and the rotation of the cutting tool to fabricate precision components effectively. Our CNC milling services are offered in materials including:

Stainless Steel

When we forge and mill stainless steel, we amplify the already excellent qualities of the alloys. Known for corrosion resistance and sustainability, stainless steel is strengthened further through forging processes by creating continuous grain flows. GL Forge is proud to perform CNC milling on numerous grades of stainless steel to fabricate high-quality components, including:

- 15-5 Stainless Steel

- 13-8 Stainless Steel

- 17-4 Stainless Steel

- 316 & 316L Stainless Steel

- Nitronic 50 Stainless Steel

Advantages of GL Forge’s CNC-Milled Components

When we forge your custom components, we craft high-quality parts designed to your exact specifications. Our CNC milling services are designed to take these parts to the next level. Advanced milling tools allow us to create a variety of slots, holes, impressions, and shapes in your open-die forged components.

When you need absolution precision or specialized customizations, CNC milling services from Great Lakes Forge are the best solution. We provide world-class CNC milling and CNC machining services for your custom part and component needs. Additional benefits of working with us for CNC-milled parts include:

- Cost-effective approach to producing prototypes & short runs

- High dimensional tolerances

- Smooth finishes

- Near-limitless shape possibilities

Why Choose Great Lakes Forge?

Great Lakes Forge has achieved the following certifications for your CNC milling service needs:

Contact Us for Custom High-Quality CNC Milling Services

Contact GL Forge for more information regarding our advanced CNC milling services, or request a quote for further pricing details today. Great Lakes Forge is your premier source for advanced CNC milling solutions.

Note: Our CNC machining capabilities are currently limited to carbon steel, alloy steel, and stainless steel forgings.