About Great Lakes Forge Inc.

Great Lakes Forge Inc. is an American metal forging company with over 60 years of steadfast commitment within the custom forging industry. As a traditional open-die forging supplier and manufacturer, our vast experience encompasses three generations of family ownership. This fortitude within the custom forging industry provides Great Lakes Forge with a better in-depth feel for the industry than most other open die forging companies. With Great Lakes Forge Inc., you can rely on industry-leading open die forging capabilities, premium materials like Stainless Steel 13-8, fast order turnaround, and friendly service.

Our History: A Trusted Open Die Forging Supplier and Manufacturer

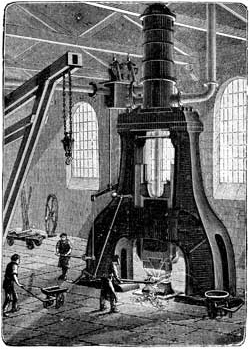

Our company's history can be traced back to the early 1900s when a steam hammer was relocated from Chicago to Grand Rapids, Michigan, laying the foundation for our forging operations. In 1946, the business was acquired by its current family owners, who built it into a thriving hammer shop and tool steel distributor.

In the early 1970s, we expanded our capabilities with the addition of a hydraulic press. Later, the tool steel segment of the business was sold to focus on forging. By the late 1980s, the press was relocated to our current facility in Traverse City, Michigan, where we continue to build on our legacy as a trusted open die forging supplier and manufacturer.

A Smaller, Faster Steel Open Die Forging Company

As metal forging companies go, Great Lakes Forge is small in size, allowing us to offer superior service and fast turnaround on custom forgings. When other steel forging manufacturers can't meet your delivery requirement or are not living up to their promises, Great Lakes Forge continues to maintain a high percentage rate of quick, on-time deliveries. As a smaller and privately owned metal open-die forging supplier and manufacturer, you can count on Great Lakes Forge for:

- Shorter lead times

- Flat line management team

- Flexibility

- No parent company with mixed agendas

- Belief that your business means a lot; you're not just another account

- Greater attention to detail

- The attitude that "bigger is not always better"

Open Die Forgings Made in the USA

Great Lakes Forge is proud to be an American-owned and operated company. We manufacture all our open-die forgings in the United States, following strict quality control processes to ensure that every forging we produce meets domestic standards. When you get your custom forgings from GL Forge, you can trust that you'll receive superior-quality components, fast delivery, and the reliability that comes from partnering with a US-based company.

An Inventory of Premium Forging Materials: 13-8 Stainless Steel, Carbon Steel, and More

We use only the finest materials to produce open-die forged parts. Our premium forging materials include:

- 15-5 PH Stainless Steel - 15-5 PH stainless steel is a martensitic precipitation hardening steel that provides high strength and high hardness qualities. It also offers corrosion resistance greater than that of straight chromium grades such as 410. It can be compared to chromium-nickel grades.

- 13-8 Stainless Steel - The nature of 13-8 stainless steel's closely controlled chemical composition and microstructure give it a higher level of useful mechanical properties under severe environmental conditions than other ferrous metals can provide.

- 17-4 PH Stainless Steel - This tough and rugged steel has numerous beneficial qualities, including high strength and hardness, good galling and stress corrosion resistance, exceptional oxidation resistance, and excellent overall corrosion resistance.

- 316 & 316L Stainless Steel - 316 stainless steel is a molybdenum-bearing austenitic material that exhibits various beneficial qualities, including high strength, creep resistance, rugged toughness, excellent mechanical qualities, and good corrosion resistance.

- Nitronic 50 Stainless Steel - Nitronic 50 stainless steel is an austenitic alloy with added nitrogen that provides numerous beneficial qualities over 316 stainless steel, including increased strength, greater corrosion resistance, and double the yield strength.

- Nitralloy 136 and 135m - Nitralloy 135 and 135m are steel alloys specifically designed for nitriding, offering enhanced surface hardness and excellent corrosion resistance without the risk of distortion common in other hardening processes.

- Carbon Steel - Carbon steel open-die forgings offer exceptional impact strength, production efficiency, cost-effectiveness, and a tight grain structure, making carbon steel a great material for many industrial applications.

Custom Forged Parts We Manufacture

We manufacture a wide range of custom-forged parts in various shapes and sizes to meet the unique requirements of our customers. From standard shapes to parts with custom dimensions, we can create forgings tailored to your specific needs, all with industry-leading turnaround times. Custom forged parts we manufacture include:

- Blocks & Rectangles

- Flats

- Rounds, Discs, & Sleeves

- Hubs, Spindles, & Stepshafts

- Custom Forged Crankshafts

- Steel and Stainless Steel Shafts

- Stainless Steel Blocks

- Stainless Steel Fluid Ends

Secondary Services for Tight Tolerances and Superior Surface Quality

We also offer a range of advanced secondary services designed to enhance the performance characteristics of your forgings. Our secondary services include:

- Heat Treating: Heat treating provides enhanced strength, wear resistance, durability, and toughness

- CNC Machining and Milling: We use our precision CNC machining and milling equipment to produce parts with tight tolerances

- CNC Turning: Our CNC turning capabilities make cylindrical components with exacting precision

An Open Die Forging Supplier and Manufacturer for the Most Rugged Industries

We serve a wide range of industrial customers nationwide. Our customers know they can count on Great Lakes Forge Inc. to deliver forged components that meet the performance standards required for their industrial environments. The industrial sectors we serve include:

If You're Looking for Open Die Forging Companies You Can Trust, GL Forge is Your Solution

Contact us for more information on our company and our custom forging capabilities. For pricing information on your orders, request a quote today. GL Forge is your source for custom open die forgings made in the USA.

Start Your Quote